JS-14A Mechanical Type + Mixer Function

Automatic Quantitative Liquid Filling & Packaging Machine

Machine Features:

- Mechanical type operation with 1/4 motor, reducer, chains, and gear.

- Piston injection filling, filling volume and packing speed adjustable on the machine directly.

- Hopper equip with speed adjustable mixer device.

- Suitable for packaging product with small ingredient.

- PLC controlled photocell device with auto tracing function.

- Patent design anti-drop filling ensure clean sealing performance.

- Safety sealing line at side with tight sealing performance.

- All component in direct contact with product are made with stainless steel or food sanitary standard.

- Individual Temp. controller with PID function for each sealing part.

- Bag width is adjustable by changing bag former guide.

Optional Device:

Date coder, double jacketed heated hopper, level indicator, mixer device, output conveyor, nitrogen air connector, quantity warning, stainless steel frame…etc., and other required device upon request.

Applicable Products:

- Food related, such as: oil, tomato ketchup, soy sauce,chicken essence, paste, chili sauce, honey, juice, wasabi, mayonnaise, jelly…etc.

- Cosmetic related, such as: lotion, cream, shampoo, conditioner, foundation…etc.

- Other items, such as: grease oil, biotechnology product, and other liquid & paste products.

Applicable Film:

Double layer heat sealable laminated film, such as: PET+LLDPE, PET+MPET+CPP, PET+PE+AL+LLDPE, Nylon+LLDPE …etc.

Sealing Type:

JS-14 A Mechanical Type+Mixer Function

Elementor Pro

View Details!

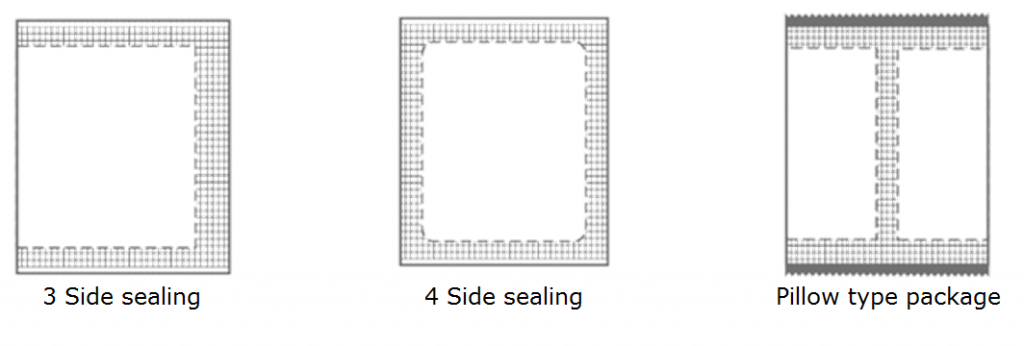

Sealing Style

3 sides, 4 side or pillow type packaging(one option)

Motor

1/4HP Motor

Power

220V, 50 or 60 Hz, single phase(upon request)

Film Width

60-140 or 80-220mm

Bag Length

50-120 or 70-160mm

Filling Weight

1-10 / 10 – 30 / 30-80 / 80-150 (varies with product density)

Packaging Speed

About 20-60 bags/min

Machine Dimension

80 x 85 x 215cm(L x W x H)

Net Weight

480kg

Note:

- Other packaging sizes available upon request.

- Filling range & Packaging speed will be differ from product density, weight & film.

- 6kg/cm2 compressed air with dry air filtering system self-prepared is required.